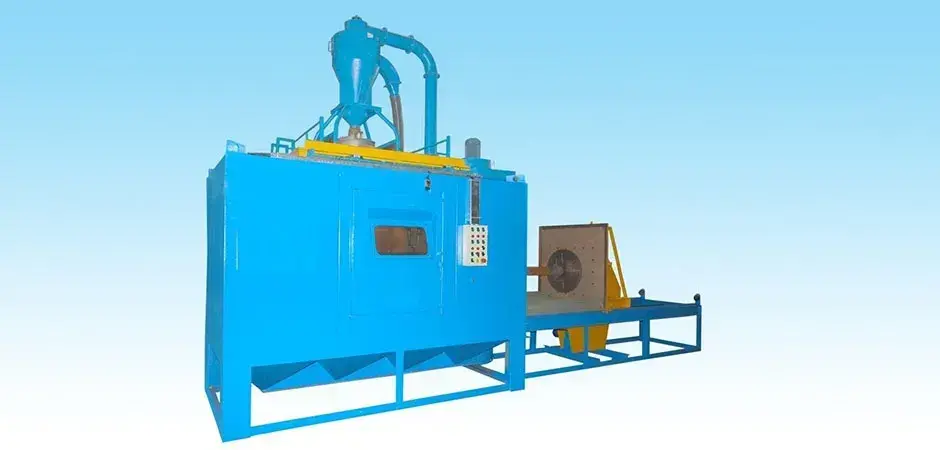

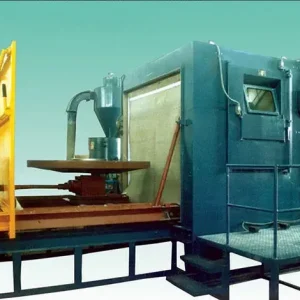

- Precision Etching: Our roll etching machines ensure precise etching and roughening of rolls used in rolling mills, enhancing surface adhesion and performance.

- Automated Operation: Designed for automated operation, these machines optimize productivity and reduce manual labor, improving operational efficiency.

- Advanced Etching Technology: Utilizing direct pressure principles, our machines achieve uniform etching results across roll surfaces, maintaining consistent quality.

- Customizable Configurations: We offer customizable machine configurations to accommodate various roll sizes and specifications, ensuring versatility and compatibility with specific industrial requirements.

- Durable Construction: Built with robust materials and components, our roll etching machines are durable and reliable for continuous operation in demanding industrial environments.

- Comprehensive Support: We provide comprehensive after-sales services including installation, training, maintenance, and technical support to ensure seamless machine operation and customer satisfaction.

Our roll etching machines in Pune are designed to meet the stringent demands of rolling mills and related industries, providing precise and efficient solutions for roll surface preparation. Automated for enhanced productivity and equipped with advanced etching technology, these machines deliver consistent and high-quality results.

Versatile and adaptable, they accommodate various roll sizes and specifications, offering tailored solutions to optimize surface preparation processes. Built with durability and reliability in mind, our machines ensure long-term performance in challenging industrial environments, supported by comprehensive after-sales services.

Why Choose Aerowheel Surface Finishing for Roll Etching Machines in Pune?

- Expertise and Innovation: With specialized knowledge in roll etching technology, we innovate to deliver high-performance machines that meet industry standards and exceed customer expectations.

- Quality Assurance: Our machines undergo rigorous quality checks to ensure durability, reliability, and consistent performance in roll surface preparation applications.

- Customer-Centric Approach: We prioritize customer satisfaction, offering customized solutions and exceptional service to optimize roll surface preparation operations effectively.

- Global Reach: Beyond Pune, we serve a global clientele, providing reliable roll etching machines that enhance productivity and efficiency in rolling mill operations.

Aerowheel Surface Finishing is your reliable partner for roll etching machines in Pune. Contact us today to explore how our advanced solutions can elevate your industrial roll surface preparation processes effectively.

Reviews

There are no reviews yet.