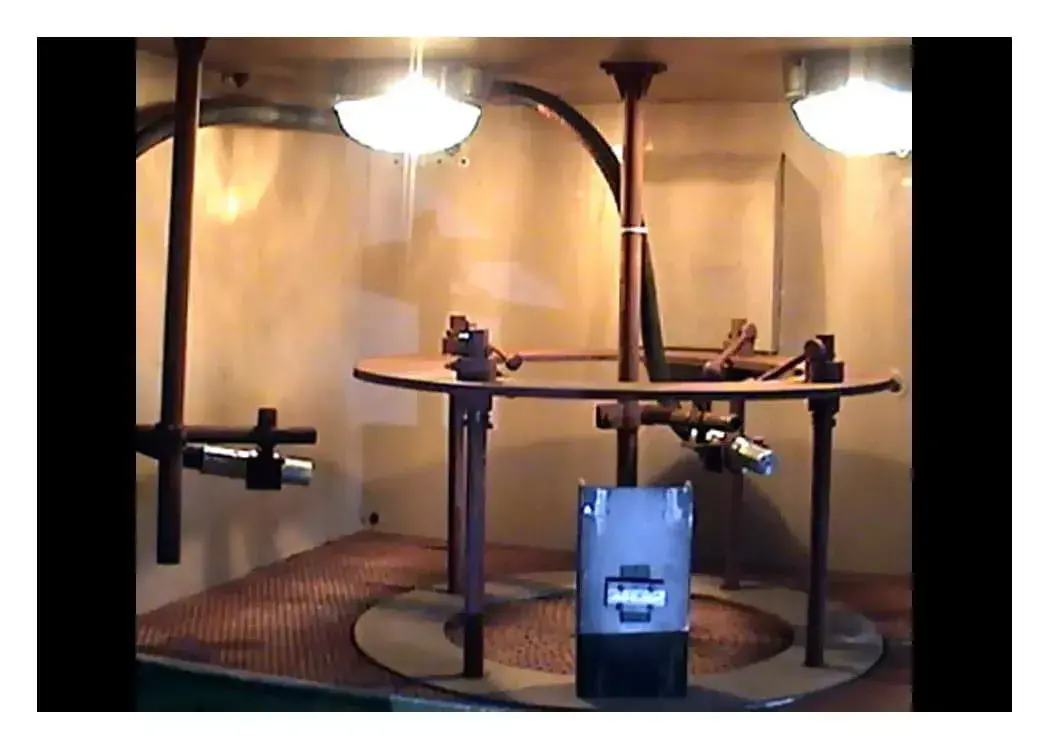

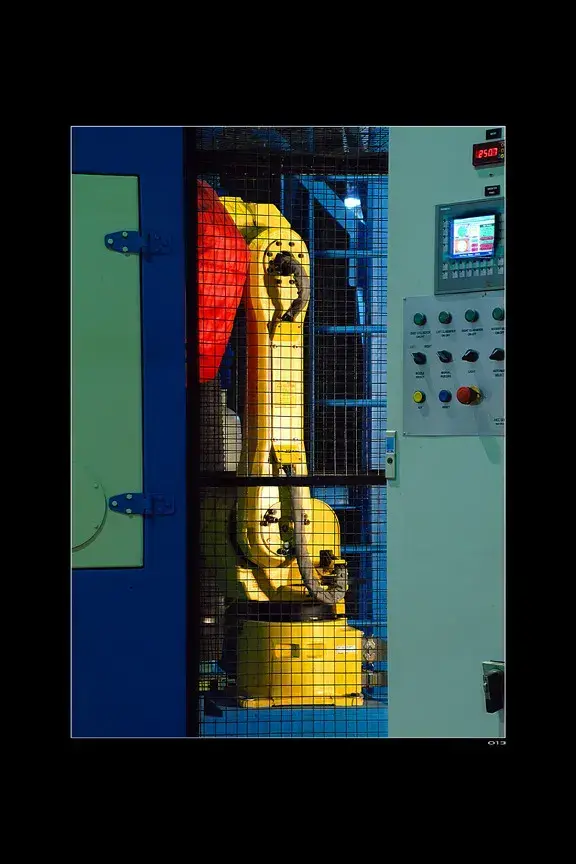

- Advanced Technology: Our shot peening machines employ state-of-the-art technology to induce compressive stress on surfaces, significantly improving fatigue resistance and extending component lifespan.

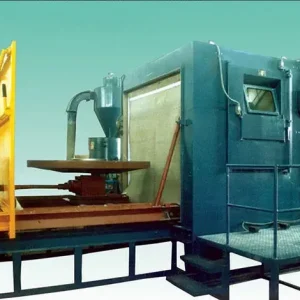

- Customized Solutions: We offer tailored shot peening machines designed to meet specific industry requirements, ensuring optimal performance and efficiency.

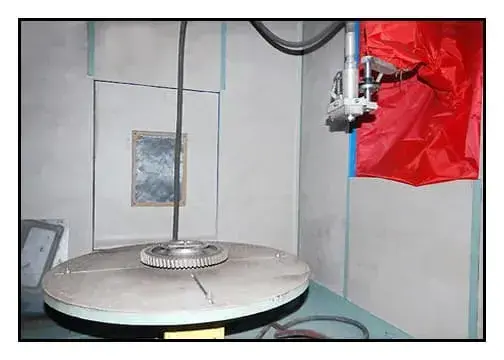

- Precision Engineering: Engineered for precise shot delivery and control, our machines ensure uniform coverage and consistent peening results on various components.

- Robust Construction: Built with high-quality materials and components, our machines are robust and durable, capable of withstanding demanding industrial environments.

- Comprehensive Support: We provide comprehensive after-sales services, including installation, training, maintenance, and technical support, to maximize machine uptime and operational efficiency.

- Industry Applications: Our shot peening machines find applications across diverse industries such as automotive, aerospace, and manufacturing, enhancing the durability and performance of critical components.

Our shot peening machines are designed to enhance surface durability and performance in Pune’s industrial landscape. Using advanced technology, they apply compressive stress to surfaces, boosting fatigue resistance and extending component lifespan. Customized solutions ensure machines meet specific industry needs, delivering efficiency and optimal performance. Engineered for precision, our machines provide uniform shot delivery and coverage, ensuring effective peening results. Built with durable materials, they withstand rigorous industrial operations. Comprehensive after-sales support, including installation, training, maintenance, and technical assistance, ensures maximum reliability and operational efficiency.

Why Choose Aerowheel Surface Finishing for Shot Peening Machines in Pune?

- Expertise and Innovation: We leverage our expertise and innovative approach to deliver cutting-edge shot peening solutions that meet industry standards and exceed customer expectations.

- Quality Assurance: Our machines undergo stringent quality checks to ensure durability, reliability, and consistent performance.

- Customer-Centric Focus: We prioritize customer satisfaction, offering personalized solutions and outstanding service to meet specific operational requirements effectively.

- Global Presence: Beyond Pune, we serve a global clientele, providing high-performance shot peening machines that enhance component durability and performance.

Aerowheel Surface Finishing is your trusted partner for shot peening machines in Pune. Contact us today to explore how our advanced solutions can optimize your surface enhancement processes effectively.

Reviews

There are no reviews yet.