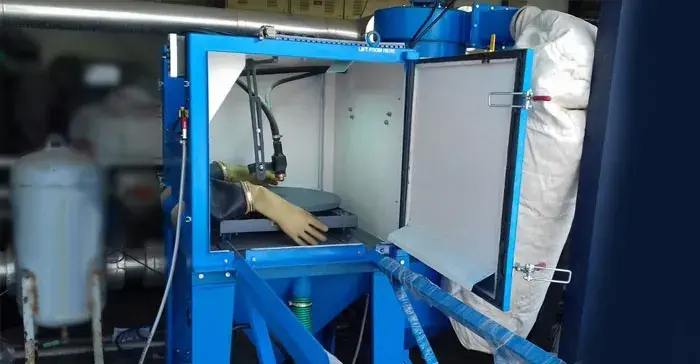

- Cost-Effective Surface Cleaning: Our suction/vacuum blast cabinets offer efficient and economical cleaning of surfaces, removing contaminants and preparing surfaces for further processing.

- Versatile Applications: Ideal for industries such as automotive, aerospace, and electronics, accommodating a wide range of component sizes and materials.

- Induction Suction Principle: These cabinets utilize an induction suction principle for effective abrasive blasting, ensuring optimal cleaning results with minimal abrasive consumption.

- Customizable Designs: We offer customizable cabinet configurations to meet specific industrial requirements, optimizing cleaning efficiency and process control.

- Durable Construction: Built with high-quality materials, our cabinets are robust and reliable for prolonged operation in demanding industrial environments.

- Comprehensive Support: We provide comprehensive after-sales services including installation, training, maintenance, and technical support to ensure smooth cabinet operation and customer satisfaction.

Our suction/vacuum blast cabinets in Pune are designed to provide cost-effective and efficient surface cleaning solutions across various industrial applications. They utilize an induction suction principle for effective abrasive blasting, ensuring thorough cleaning while minimizing abrasive consumption.

Versatile and adaptable, our cabinets accommodate different component sizes and materials, offering customized solutions to meet specific industrial needs. Built for durability, they withstand rigorous operational conditions, ensuring reliable performance over extended periods. Comprehensive after-sales support guarantees seamless operation and maximum productivity.

Why Choose Aerowheel Surface Finishing for Suction/Vacuum Blast Cabinets in Pune?

- Expertise and Innovation: With specialized knowledge in blast cabinet technology, we innovate to deliver high-quality cabinets that meet industry standards and exceed customer expectations.

- Quality Assurance: Our cabinets undergo rigorous quality checks to ensure durability, reliability, and consistent performance in surface cleaning and preparation processes.

- Customer-Centric Approach: We prioritize customer satisfaction, offering tailored solutions and exceptional service to meet specific operational requirements effectively.

- Global Reach: Beyond Pune, we serve a global clientele, providing reliable suction/vacuum blast cabinets that enhance surface cleaning and preparation processes across various industries.

Aerowheel Surface Finishing is your trusted partner for suction/vacuum blast cabinets in Pune. Contact us today to explore how our advanced solutions can optimize your industrial surface cleaning and preparation operations effectively.

Reviews

There are no reviews yet.